Excellence in Monolithic Refractory Solutions

Materials, Services, and Engineering

Minimize downtime and maximize performance with Plibrico refractory solutions for industrial furnaces, kilns, and boilers. Our high alumina refractories and aluminosilicate refractories are engineered for extreme heat and long service life. For over 100 years, Plibrico has delivered monolithic refractory materials, including castable refractories and gunning refractories, supported by custom engineering, turnkey installation, and rapid repair, keeping your equipment safe, efficient, and production-ready in the harshest environments.

INDUSTRIES:

Aluminum/Non-Ferrous

Boilers

Ferrous Metals

Heat Treating

Incineration

Mineral Processing

Pollution Control

Power Generation

Steel

REFRACTORIES:

Additional Refractories

Aluminum Contact Castable Refractories

Cement Free Castable Refractories

Abrasion Resistant Castable and Gunite Refractories

Conventional Castable and Gunite Refractories

Gunite Dense Refractories

Free Flow Castable Refractories

Chemically Bonded Castable and Gunite Refractories

Insulating Gunite Refractories

Low and Ultra Low Cement Castable and Gunite Refractories

Insulating Castable Refractories

Rapid Heat-Up Castable and Gunite Refractories

Service Mixes and Refractory Mortar

Plastic Refractories

Protective and Parting Agent Coatings

Shotcrete Refractories

PRODUCTS:

Plicast 40

Plicast 31

Plibrico 60 AB

Plistix 900 F

Ultra Demon Air Set Wet Mortar

Plicast LWI 24

Plicast HyMOR 3000 KK

Durafloor II

Refractory Solutions Built for Your Harshest Heat Challenges

- 100+ Years of Expertise in Monolithic Refractory Ceramics

- High Alumina & Aluminosilicate Refractory Solutions

- Full-Service Refractory Partner: Concept-to-Completion Solutions

In the harshest thermal environments, you need refractory solutions that work as hard as you do. That’s where Plibrico comes in, delivering the heat control, durability, and performance to keep your operation safe, efficient, and productive.

For over 100 years, we’ve specialized in monolithic refractory ceramic technology for industrial furnaces, kilns, and boilers, built to withstand extreme heat, severe thermal cycling, and the most demanding operating conditions. Our aluminosilicate and high-alumina refractories are engineered for long service life, equipment protection, and optimal performance.

From premium ceramic refractory materials and precast shapes to custom engineering, turnkey installation, and rapid repair services, we provide everything you need from a single, trusted source. With Plibrico, you get more than products, you get a partner committed to delivering safe, reliable, and lasting refractory solutions that keep you running strong.

Plibrico Refractories for EveryIndustry

Aluminum/Non-Ferrous Metals

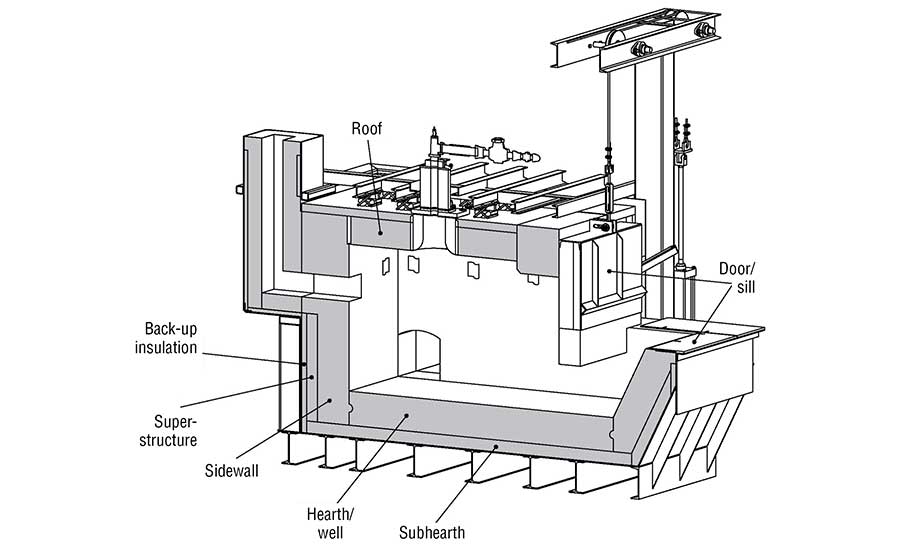

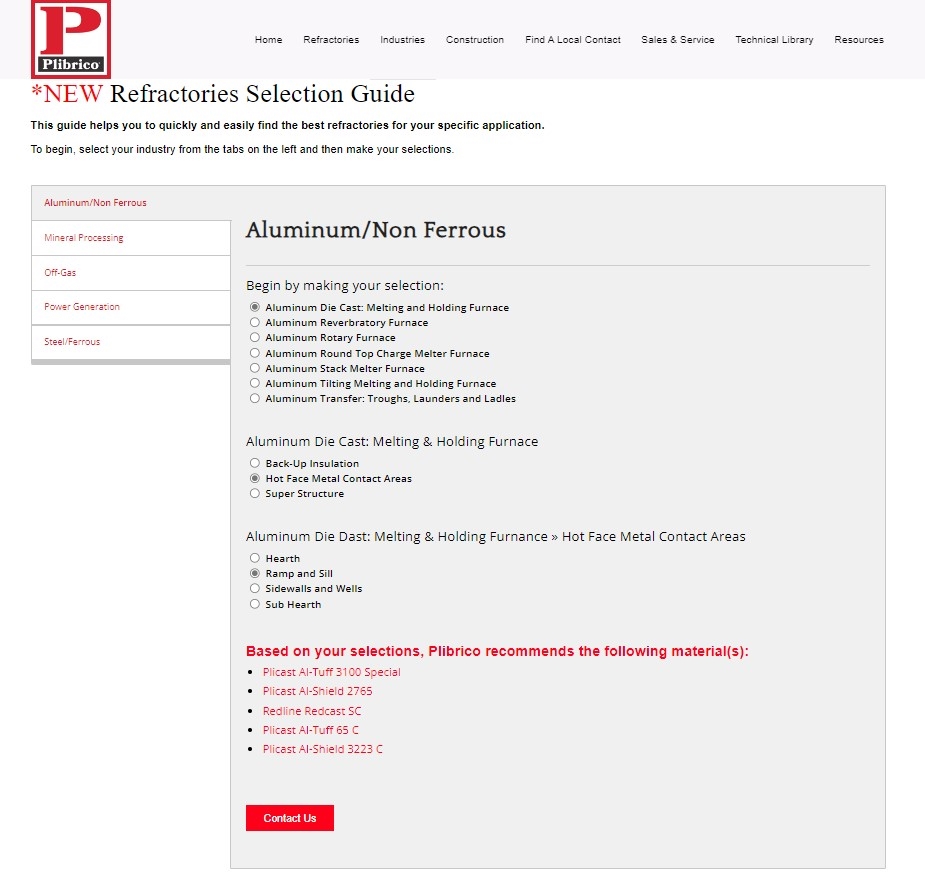

Built for aluminum processing operations, Plibrico’s refractory solutions provide superior durability, energy efficiency, and heat resistance. Whether lining large melting furnaces or crucibles, our expert-designed materials help aluminum producers improve productivity, extend equipment life, and reduce costly downtime.

Steel / Iron / Ferrous Metals

In demanding steel and ferrous metal operations, refractory reliability is everything. Plibrico’s solutions provide superior durability, heat resistance, and operational safety in extreme furnace environments. From large induction furnaces to compact roller hearth units, our expertise extends refractory life and keeps plants running smoothly.

Power Generation

Power plants demand refractories that withstand heat, velocity, abrasion, and chemical attack. Plibrico’s durable materials provide superior protection, thermal efficiency, and long service life. With rapid, reliable delivery, our solutions extend refractory performance, minimize downtime, and keep operations running efficiently.

Incineration

Incineration pushes refractory linings to the limit with extreme heat, abrasion, and chemical attack. Plibrico’s durable solutions deliver protection, efficiency, and long service life across waste-to-energy, hazardous waste, recycling, and cremation applications—minimizing downtime and ensuring reliable operation.

Boilers

Boilers operate in demanding conditions where refractory performance drives efficiency and reliability. Plibrico’s high-performance materials deliver low thermal conductivity, durable protection, and reliable performance. Our solutions enhance heat transfer, reduce energy loss, and extend boiler life keeping operations running efficiently with less downtime.

Additional Industries

Plibrico’s high-quality refractory solutions deliver durability, thermal efficiency, and dependable performance across diverse high-temperature applications. Engineered to resist heat, abrasion, and chemical attack, our monolithic refractories optimize operations, minimize downtime, and extend equipment life in industries requiring reliable refractory performance.

Pollution Control

Pollution control refractories must withstand high heat, chemical attack, and thermal cycling. Plibrico’s durable monolithic refractories provide efficient heat containment, reliable emissions control, and long service life – supporting compliance, optimizing system efficiency, and ensuring dependable performance in pollution control and thermal oxidizer applications.

Heat Treating

Heat treat refractories must withstand high temperatures, thermal cycling, and demanding industrial conditions. Plibrico’s durable monolithic refractories deliver thermal stability, efficiency, and long service life—ensuring consistent heat distribution, reliable process performance, and extended equipment life in applications like annealing, nitriding, and quenching.

Boilers

Boilers operate in demanding conditions where refractory performance drives efficiency and reliability. Plibrico’s high-performance materials deliver low thermal conductivity, durable protection, and reliable performance. Our solutions enhance heat transfer, reduce energy loss, and extend boiler life keeping operations running efficiently with less downtime.

Additional Industries

Plibrico’s high-quality refractory solutions deliver durability, thermal efficiency, and dependable performance across diverse high-temperature applications. Engineered to resist heat, abrasion, and chemical attack, our monolithic refractories optimize operations, minimize downtime, and extend equipment life in industries requiring reliable refractory performance.

Pollution Control

Pollution control refractories must withstand high heat, chemical attack, and thermal cycling. Plibrico’s durable monolithic refractories provide efficient heat containment, reliable emissions control, and long service life - supporting compliance, optimizing system efficiency, and ensuring dependable performance in pollution control and thermal oxidizer applications.

Heat Treating

Heat treat refractories must withstand high temperatures, thermal cycling, and demanding industrial conditions. Plibrico’s durable monolithic refractories deliver thermal stability, efficiency, and long service life—ensuring consistent heat distribution, reliable process performance, and extended equipment life in applications like annealing, nitriding, and quenching.

Aluminum/Non-Ferrous

Built for aluminum processing operations, Plibrico’s refractory solutions provide superior durability, energy efficiency, and heat resistance. Whether lining large melting furnaces or crucibles, our expert-designed materials help aluminum producers improve productivity, extend equipment life, and reduce costly downtime.

Steel/Iron/Ferrous Metals

In demanding steel and ferrous metal operations, refractory reliability is everything. Plibrico’s solutions provide superior durability, heat resistance, and operational safety in extreme furnace environments. From large induction furnaces to compact roller hearth units, our expertise extends refractory life and keeps plants running smoothly.

Power Generation

Power plants demand refractories that withstand heat, velocity, abrasion, and chemical attack. Plibrico’s durable materials provide superior protection, thermal efficiency, and long service life. With rapid, reliable delivery, our solutions extend refractory performance, minimize downtime, and keep operations running efficiently.

Incineration

Incineration pushes refractory linings to the limit with extreme heat, abrasion, and chemical attack. Plibrico’s durable solutions deliver protection, efficiency, and long service life across waste-to-energy, hazardous waste, recycling, and cremation applications—minimizing downtime and ensuring reliable operation.

Plibrico Technical Library

Looking for quick access to Plibrico refractory datasheets, heat-up schedules, or installation guides? The Plibrico Technical Library gives you fast, searchable access to everything you need in one place.

Find answers to common questions like “How do I install Plibrico castables?” or “Where can I find Plibrico refractory safety datasheets?” Whether you need product specifications, safety information, or best practices, our Technical Library helps you work smarter, ensure proper installation, and extend the performance and life of your refractory system.

Refractory Products for Every Challenge

Plibrico Refractories

Redline Refractories

Plico Refractories

Redi-Shapes Precast Shapes

Plibrico in the News

Our Biggest Strength is Our EmployeesCareer Opportunities

The Value of Culture at the Plibrico Company

Stay Connected - Follow Us on LinkedIn

Latest Case Study

A Better Way To Get Things Done: Refractory Insulation Case Study

A Better Way To Get Things Done: Refractory Insulation Case Study

Plibrico’s innovative refractory insulation solutions cut downtime, lower labor requirements, and extend refractory lining life delivering greater efficiency, reliability, and long-term performance for high-temperature industrial operations.

Watch How Plicast Airlite 25 C/G makes refractory installation simpler, replacing fiber and board with lightweight gunite efficiency.

Login for PliPartner Website & More

Please log in with your username and password. If you are not registered or have lost your username or password, please let us know what you need by emailing contact@plibrico.com.