[av_heading tag=’h2′ padding=’10’ heading=’Plibrico Introduces Innovative Online Refractories Selection Tool’ color=” style=” custom_font=” size=” subheading_active=” subheading_size=’15’ custom_class=” admin_preview_bg=” av-desktop-hide=” av-medium-hide=” av-small-hide=” av-mini-hide=” av-medium-font-size-title=” av-small-font-size-title=” av-mini-font-size-title=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” margin=”][/av_heading]

[av_hr class=’default’ height=’50’ shadow=’no-shadow’ position=’center’ custom_border=’av-border-thin’ custom_width=’50px’ custom_border_color=” custom_margin_top=’30px’ custom_margin_bottom=’30px’ icon_select=’yes’ custom_icon_color=” icon=’ue808′ av-desktop-hide=” av-medium-hide=” av-small-hide=” av-mini-hide=” av_uid=’av-6ijrj5′]

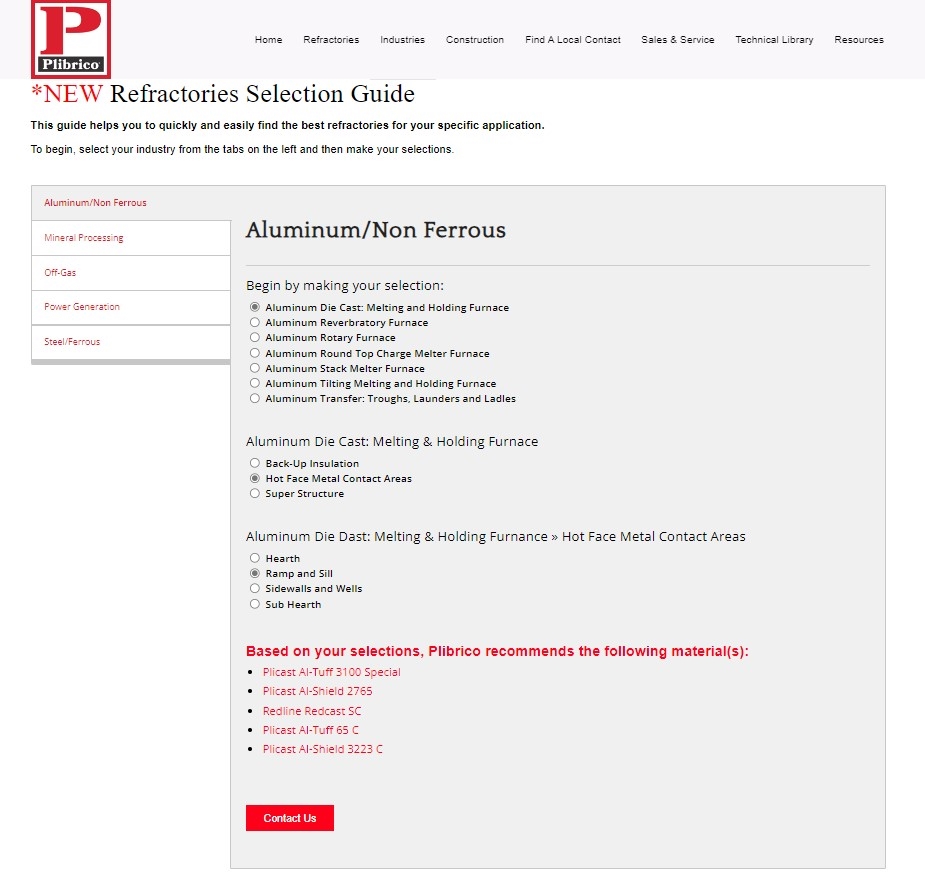

[av_image src=’https://dev.plibrico.com/wp-content/uploads/2024/01/Plibrico-Refractories-Selection-Guide-300×283.jpg’ attachment=’12254′ attachment_size=’medium’ align=’center’ styling=” hover=” link=” target=” caption=” font_size=” appearance=” overlay_opacity=’0.4′ overlay_color=’#000000′ overlay_text_color=’#ffffff’ copyright=” animation=’no-animation’ av_uid=’av-3p3prl’ custom_class=” admin_preview_bg=”][/av_image]

[av_textblock size=” font_color=” color=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” av_uid=’av-2c93kx’ custom_class=” admin_preview_bg=”]

User-Friendly Online Tool Guide Simplifies Refractory Selection for Industry Professionals

Introducing a user-friendly online refractory selection tool guide by the Plibrico Company, a premier supplier of monolithic refractories. The tool is designed to guide and empower customers with focused refractory choices tailored to their specific industry and application. Accessible at www.plibrico.com/industries, this tool is a valuable resource for refractory installers, as well as professionals in the steel, aluminum, off-gas, mineral processing, and power generation sectors.

By providing industry and equipment details, the selection tool guide identifies Plibrico refractories that offer the optimal blend of structural, thermal, and mechanical properties, along with exceptional overall performance and workability. Customers can then easily navigate to the Plibrico Technical Library by selecting one of the recommended refractories. Here, they gain access to crucial information such as technical data, installation guidelines, and safety documents.

Selecting the optimal refractory material is a critical decision that directly impacts the efficiency, safety, and overall success of a refractory project. Using Plibrico’s online tool guide that has already considered essential factors such as temperature resistance, chemical compatibility, and mechanical strength ensures that the chosen refractory material aligns with the unique demands of the application, ultimately leading to improved performance and longevity.

In detail, essential factors considered:

- Material Characteristics:

- Temperature Resistance: Ensures refractories withstand extreme temperatures, maintaining structural integrity.

- Chemical Compatibility: Prevents corrosion and erosion by selecting materials compatible with process chemicals and gases.

- Functional Performance:

- Thermal Insulation: Provides effective heat insulation, improving energy efficiency in industrial processes.

- Mechanical Strength: Enhances longevity and resistance to wear, addressing mechanical stresses in diverse applications.

- Operational Considerations:

- Stability: Ensures consistent performance by improving or maintaining heat transfer, reducing energy consumption, and enhancing production output under varying temperatures and conditions.

- Application-Specific Tailoring: Increases productivity and minimizes downtime by optimizing refractory material for industry-specific requirements.

Selecting the right refractory material is a pivotal decision that significantly influences the efficiency, safety, and overall success of a refractory project. The suitability of the chosen material for specific applications directly impacts performance, longevity, and maintenance costs. Plibrico’s refractory selection tool guide, that can be accessed at www.plibrico.com/industries, exemplifies Plibrico’s commitment to simplifying the refractory specification process, making it accessible, and ensuring accuracy. Properly specified refractories, installed by refractory experts, can significantly diminish customer maintenance needs and lead to improved refractory performance and longevity.

For those seeking additional guidance or with applications not covered by the selection tool guide database, Plibrico Customer Care can be reached at contact@plibrico-company.websitepro.hosting or 312-337-9000. Plibrico remains dedicated to providing unparalleled support and expertise to meet the diverse needs of its clientele.

[/av_textblock]